How To Build A Wood Frame To Winterize A Boat Youtube

How to: Reusable Winter Comprehend Framework

Good headroom and plenty of elbow room were prerequisites

Embrace Up

While many gunkhole owners are consumed with the annual task of hauling and storing their vessels for the wintertime, others are prepping for the cold months by turning theirs into a stationary den. I liveaboard in the snowbound Northeast, where most liveaboards cover their decks by erecting a temporary structure to be wrapped in heat-shrinkable plastic sheeting. Such a shrink-wrapped embrace adds a layer of protection and comfort for the ship and her crew by helping to shed rain and snow, reduce condensation and provide passive solar heat during the day.

Last winter I decided to build a seasonally reusable structure that offers plentiful space to do the only thing I love more than than sailing—gunkhole work. Hither are the steps I took, from conception to realization, in making a functional wintertime boat shop under the shrink-wrapped shelter on my Tayana 42, Eclipse i. Fifty-fifty if you don't want an onboard workshop, this frame concept will work for simply almost whatever boat.

Choosing Materials: Galvanized electric conduit is the virtually common pick for reusable shrinkwrap frames. Information technology's a great option and allows for easy assembly. It's also compact when broken down, and quite stiff. I previously congenital a frame from metallic conduit. Withal, I decided to rethink it this time around. Wood is less expensive, faster to cutting, doesn't crave bending and is lighter.

Roof Pitch: The weight of the snow on a frame tin can arrive collapse, so a proper pitch on the roof is necessary to allow it to slide off. Besides much of a pinnacle, all the same, makes the structure extremely hard to cover in plastic since the peak is out of reach. The angle at the height of my structure is 30 degrees. Stubborn snowfall can exist persuaded from its perch past banging at information technology from the within.

Elbow Room: From previous experience, I knew that proper headroom isn't the but thing necessary under the wrap. Elbow and shoulder room is disquisitional while walking forth the side decks.

Ease of Assembly: If yous're going to reuse your frame, be sure to characterization all of the parts. Each of my frames is designed to fold upwardly after I remove the wingnuts and bolts from each plywood joint.

Clear shrinkwrap provides calorie-free and acts like a greenhouse on winter days

Watertightness: Unstepping the mast was a critical function of making my frame easy to embrace and completely watertight. It was also disquisitional for positioning a work bench over the mast pulpits. If you're not setting up an on-deck piece of work station, you may well want to leave the mast in place, in which case y'all'll have to design your frame around it.

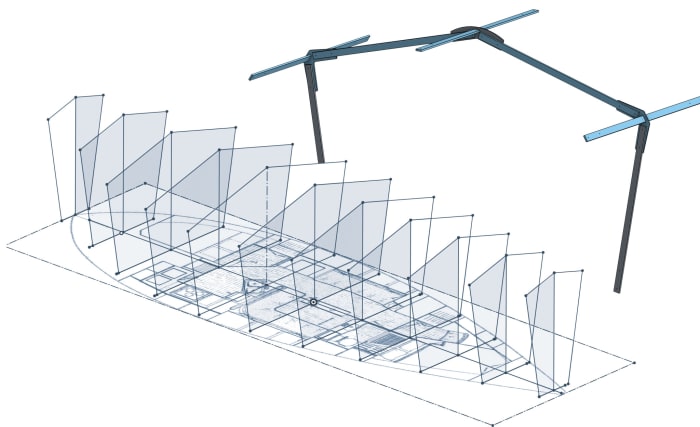

CAD Software: I'm not formally trained in CAD software or in drafting. Nonetheless, modern figurer drafting software has really lowered the bar for doing work like this. I used OnShape (onshape.com), for its free web-based CAD software. It'southward also piece of cake to learn how thanks to an abundance of online tutorials. To design the frame, I took an image of the deck profile of my gunkhole and imported it into the design. By stretching it lengthwise to its 42ft LOA I then had a very close representation of Eclipse ane's profile. This served as the guide for the lines I drew to represent each frame.

I also used the software to blueprint the plywood frame joints, which I paid to take cut at Artisans Asylum (artisansasylum.com), my local "maker space."

The Workbench: I am very lucky to have stable mast pulpits on deck that, without a mast in place, would support a table. The workbench was the first thing to be synthetic and continues to exist the pièce de résistance throughout the evolution of wintertime boat projects.

Construction Directions: I manually took the dimensions from the CAD drawings and created a spreadsheet with the lengths of the various timbers that would make up the frames. I cut these accordingly. Each of the frame legs was notched with a router and then that they would sit securely over my slotted toerail. I created jigs for all notching and drilling, which made the production of the parts that much faster and easier.

Mistakes: Non accounting for the rise of the sheer both fore and aft was a critical oversight on my part. When making my original CAD drawings, I designed all the frames on a flat plane. In the end, everything worked out OK, simply associates was definitely more difficult than it should take been, as the wood used for the fore and aft ridge elements needed to be bent into place.

Assembly: I have one affair to say—the more hands the better!

Phil Gutowski runs BoatRX, a marine systems company, in Boston, Massachusetts. Contact him via Boatrx.co

October 2017

Related

Charter: Lake Tahoe

A sail on Lake Tahoe has been on my bucket listing since the day I first laid eyes on information technology, and come up hell or high water, I decided I was going to anytime charter a gunkhole there. North America'south largest and deepest alpine lake, Tahoe sits at 6,225ft above sea level and straddles the ...read more

Escape from New York Part one

I was never supposed to have my boat through New York City. After getting sucked backward through the Cape Cod Canal on my manner south from Maine, when the speed of the current exceeded the maximum speed of my little electrical auxiliary, I wanted nothing to do with Hell Gate and ...read more

A Watermaker Upgrade

As a classic-boat sailor, I've long held that simpler is the better. I still think this is true: a simpler boat is cheaper, she has less gadgets to break down and in that location's a certain satisfaction in knowing you're able to handle a flake of discomfort. Thus, for a long fourth dimension, I sailed ...read more

Sailing Speed Records

Although the 1903 defender of the America's Loving cup, Reliance, was deemed a "racing freak"—the gunkhole pushed design rules to their limit and couldn't be beaten, at least in very specific weather—designer Nat Herreshoff was nonetheless onto something. A century after, purpose-congenital ...read more than

Chartering with Non-sailors

3 tips on managing the madness First-fourth dimension charterers and get-go-time sailors aren't at yet matter. One grouping may struggle with beginner chartering issues, similar sailing a multihull, catching a mooring or dealing with base of operations personnel. For the other group, though, ...read more

A Gulf Stream Crossing at Nighttime

Fifty-fifty the dome of lite glowing above the metropolis behind u.s.a. had disappeared as if swallowed in a gulp past Noah's whale. The moon was absent-minded. Non a star twinkled overhead. The nighttime was so dark we could have been floating in a pot of blackness ink. The only artificial lights to be seen ...read more

Summer Sailing Programs

Every year, countless parents notice themselves navigating the do's and don'ts of enrolling their children in a summertime acquire-to-sheet program for the commencement time. While the prospect of getting your kid on the water is exciting, as a sailing camp program director, in that location are a lot of ...read more

Find to Mariners: U.South.A! U.South.A! (Well, sorta…)

Some thoughts on a couple of recent developments on the U.South. racing scene that are more than a niggling at odds. To start with, congratulations to the United states of america Sailing Squad (USST) and its outstanding showing at the 53rd French Olympic Week regatta in Hyeres, France, with non one but ...read more

Source: https://www.sailmagazine.com/diy/how-to-reusable-winter-cover-framework

Posted by: robinsonlitaltalat.blogspot.com

0 Response to "How To Build A Wood Frame To Winterize A Boat Youtube"

Post a Comment